What Is Standing Seam Metal Roofing?

Comparisons, Types, & Uses

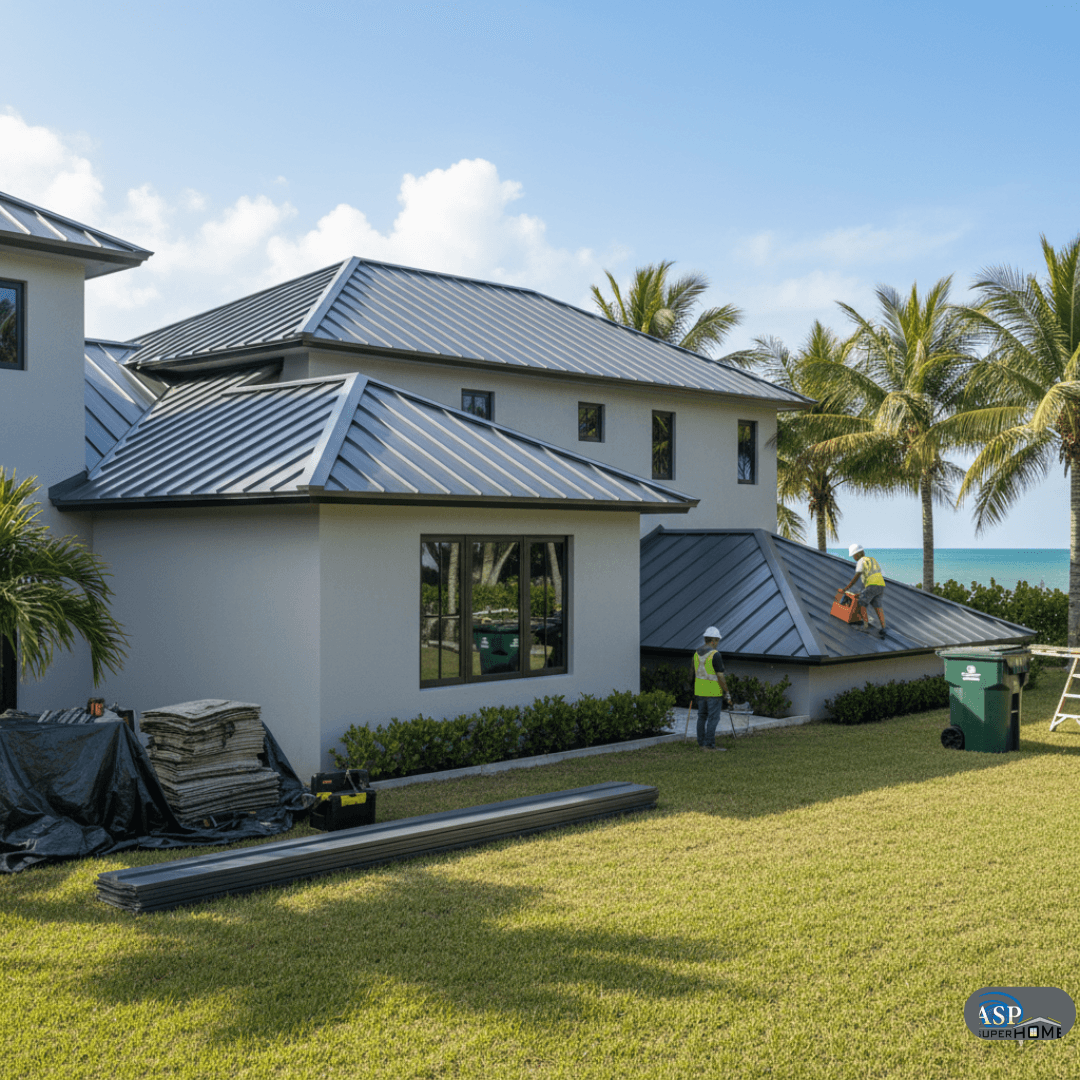

Over the last decade, standing seam metal roofing has rapidly become one of the top roofing options in South Florida for homeowners and commercial buildings. The adverse weather conditions in Miami, Broward and Palm Beach which include intense heat and sunlight paired with severe tropical rainstorms and heavy winds have pushed manufacturers to design a product that would perform well despite the aforementioned conditions. From these demands came standing seam metal roofing.

The Current Attraction to Metal Roofing

A standing seam metal roof is an attractive option for several reasons, the most important of which is its durability. When compared to traditional roofing materials like clay or cement tile and shingle, a standing seam metal roof will last much longer with less maintenance.

What Makes Standing Seam Metal Roofing a Truly Superior Choice

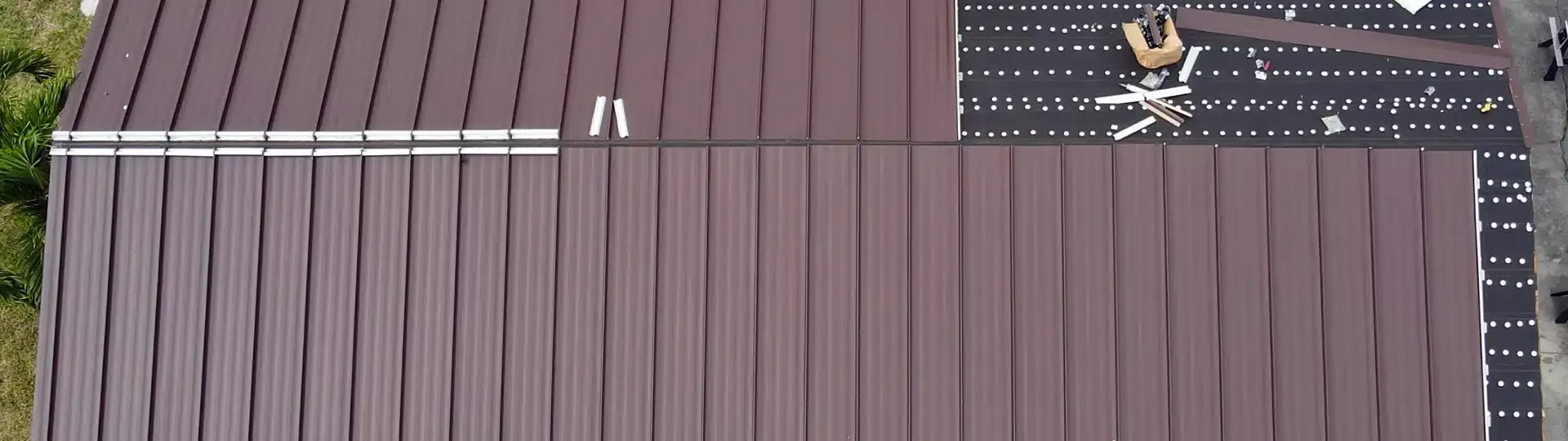

There are several features and characteristics of standing seam metal roofs that make them a superior product when compared to other roofing materials. The main feature is the seam that is formed when connecting two adjacent panels during installation. The main function of the seam is to cover the clips and screws used to anchor the metal panels to the deck, protecting them from water. By doing so, the anchors are protected from corrosion over time. Because the standing seam panels are made of metal, there is no chance of cracking and the anchors can go for decades without being exposed to water damage.

There Should Be No Exposed Fasteners

The anchors or fasteners described above are well protected in standing seam roofing but this is not the case in other types of metal roofs. Ideally, there should be no exposed fasteners so they can’t be stripped by running water and rain. Exposed fastener panels typically have much shorter lifespans due to the fact the runoff water strips the fastener creating an entry point for more water to leak into the underlying structure. The stripping of the fastener also weakens the strength of the anchor during heavy wind speeds.

What is the Average Lifespan for a Standing Seam Metal Roof?

Standing seam roofs have a longer lifespan than every other roofing material including alternative metal roofing systems without concealed fasteners. A quality standing seam metal roof will last for 40-70 years with little upkeep.

The Two Main Metal Roofing Contenders – Metal Tile and Standing Seam

There is a new metal panel type that looks like traditional tile from a manufacturer called Worthouse. This metal roofing system is anchored with exposed fasteners but it uses a self-sealing anchor with a corrosion-resistant stainless steel head in order to prevent the issues described above. The product comes with a 50-year warranty and is typically installed with a water-tight peel-and-stick membrane underneath just in case.

How Much Does Standing Seam Metal Roofing Cost?

The price for standing seam will vary depending on the quality of the metal, the experience of the installer, the type of metal used and the location of the install. For an average one-floor home in Miami or Broward Counties using Galvalume, a standing seam metal roof costs between $12.50 to $13.50 per roof square.

Higher Cost

Looking at this pricing, it is apparent that a standing seam metal roof system is more expensive than traditional asphalt shingles, clay/cement tile, or even classic metal roofing systems. There are several reasons for this.

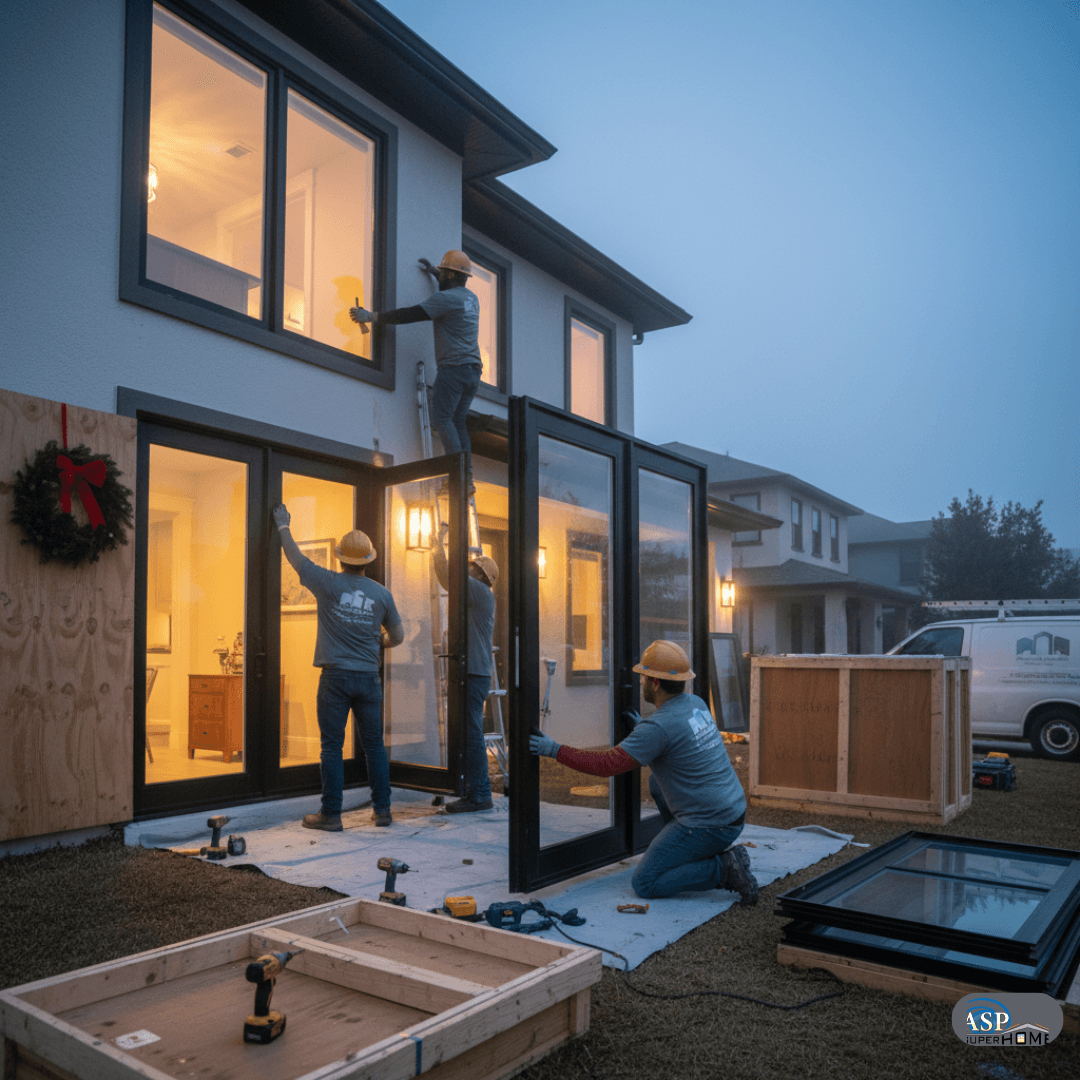

It’s a Labor-Intensive Installation Process

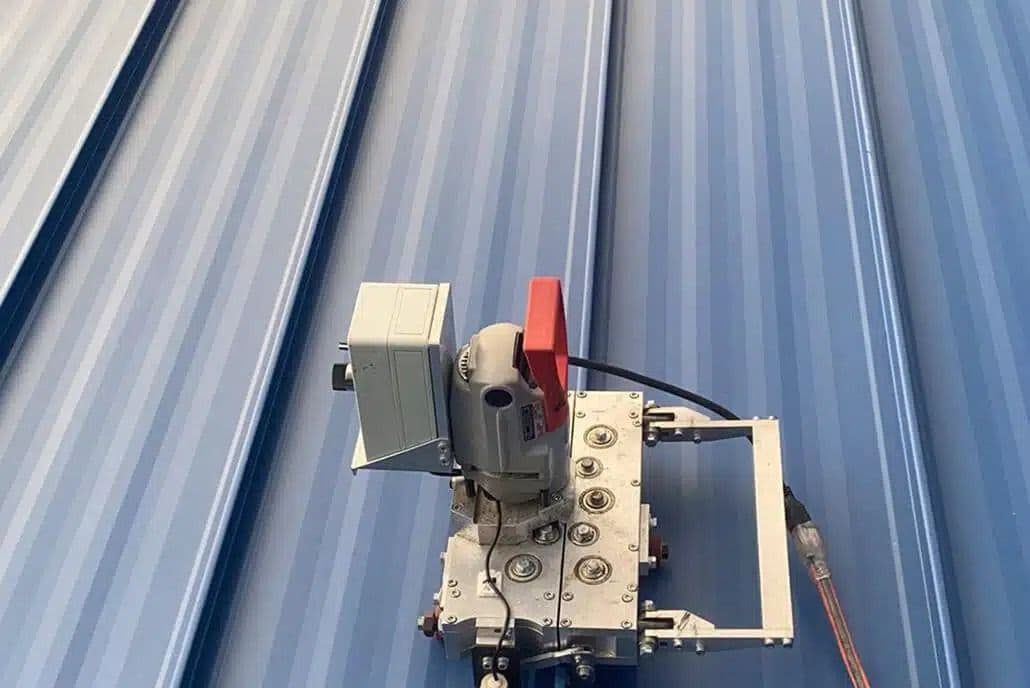

A standing seam roof installation is more difficult than all other roof types. For one, metal panels can be quite long, and manipulating metal on a hot roof requires strength and focus. Mechanically seamed panels are joined with a machine operated by hand. Special connecting pieces have to be bent by hand.

How Long Does It Take to Install a Standing Seam Metal Roof?

It’s not possible to give an accurate timeframe for how long it will take to install a metal roof. Complex roof projects requiring many metal cuts will take much longer than a simple two-sided roof.

CONTACT US NOW: (786) 625-7192

The Leading Professionals In Roof Installation In South Florida. Let Us Prove It To You!

Types of Standing Seam Metal Roofing Panels

There are several classifications for standing seam metal roofing used in residential applications. One of the most important differentiators is the type of metal from which the actual panels are fabricated.

Metal Type

For properties located a mile or more from the South Florida coastline, Galvalume is the best option. This type of metal is an alloy made from steel and aluminum. The steel provides strength while the aluminum is used for its anti-corrosion properties.

Different Material Options for A Standing Seam Roof

It is possible to get standing seam roofing in aluminum which is the best choice for a building project located within a mile of seawater. Roofing contractors typically recommend this product to their customers only when necessary because aluminum standing seam systems are 20-30 % more expensive than their Galvalume counterparts.

Panel Width and Metal Gauge

Typically, standing seam panels will have a 16″ separation between the seams. Coil sizes by major manufacturers can come in different width depending on material type but the finished product has standardized widths once attached to the roof decking.

What Gauge is Standing Seam Metal Roofing?

The gauge of standing seam metal roofing panels varies dependent on the material. Aluminum is typically offered in .032 and .040 while galvalume is offered in 24 and 26 gauge. While 26 gauge can sometimes be used in Miami-Dade and Broward if accompanied by thick enough anchors, 24 gauge is typically needed in order to fulfill the necessary strength required by the climate conditions and local codes.

Standing Seam Panels and Profile Types

A standing seam roof system can have slight variations in look depending on both the texture of the flat section of the panel as well as the shape of the raised seams.

Oil canning is a common problem for mechanically seamed systems. Oil canning occurs when the panels are installed over an existing roof deck that is warped and uneven. The flat metal will appear warped and dented when light hits the roof surface at an angle.

For that reason, standing seam metal roof panels are typically striated which creates the illusion of a completely flat surface even though it is not.

Mechanical Lock Profiles

There are also a number of different mechanical lock profiles that are employed. Different fabricators will employ different seam types depending on the ease of installation and relative strength. A double lock profile is preferred for the South Florida climate, particularly Miami, Broward, and Palm Beach.

A double lock standing seam concealed fastener system will protect you better against water intrusion. Because the vertical legs are folded over twice, the seam itself is stronger and less likely to come undone under adverse weather conditions.

Double lock standing seam can also be used on lower pitch roofs with some products having approvals for pitches as low as 1/12.

What Is Snap Lock Standing Seam Metal Roofing?

Because mechanically seamed roofs are more difficult to install, a snap lock system was developed in order to easily attach the female leg of an adjacent standing seam panel by snapping it into place. A snap lock standing seam system is also very secure and watertight, making it a viable solution for this local market.

Snap Lock vs. Mechanical Lock Panels

Snap Lock panels are a great alternative but there are a few drawbacks when compared to a metal roof installation with mechanical seam. Snap Lock systems despite being easier to install are more expensive. In addition, due to the higher potential for low-sloped roofs to leak, snap lock systems cannot be used on low-sloped roofs.

What is the Difference Between Standing Seam vs Corrugated Metal Roofs?

Corrugated metal roofing is a simple, exposed fastener system that uses weak anchors and thin gauge metal panels that overlap each other. While often used in island areas or throughout the world as a cheap and durable roofing solution, in truth corrugated metal roofing panels’ thickness and along with their anchors means these systems lack the strength to resist hurricane-force winds the likes found in Miami and Fort Lauderdale.

They are typically painted with an inferior finish that fades quickly and the exposed fasteners result in rust at the anchor points leading to aesthetic and physical performance.

Option for Engineered Metal Roof Systems Tested to Perform to High Standards

Homeowners will be happy to know that every roof replacement in Miami or Broward must be performed using a product that has been tested in a laboratory under hurricane categrory 5 like conditions.

Not to Be Used on Flat Roof Structure

Most standing seam metal roof systems do not have approval for flat roof use in Miami or Broward areas. However, many have a 1/12 min pitch which is close to flat. It is important to read the NOA or engineering documents to determine the lowest pitch on which the metal roof system is installed.

Battens For Metal Tile Panels

Standing seam metal roofing systems are one of the strongest possible solutions for a homeowner’s roof replacement. Previously, a product like metal tile was as strong but only if installed with wooden strips known as battens which are anchored to the roof deck before attaching the metal tile panels. This means a lot of added material and labor costs for a professional roofing contractor.

Recently, a company called Worthouse obtained direct-to-deck approval in Miami-Dade, Broward, and Palm Beach for its metal tile roof solution and it rivals standing seam metal roofing’s wind resistance values.

Repairs and Maintenance

One of the best characteristics of a metal roof is that once a metal roof is properly installed, it requires little to no maintenance thanks to the metal’s durability.

Mold Resistance

Metal roofing material naturally resists mold.

Is a Metal Roof Noisy in the Rain?

This is a big misconception about metal roofs in South Florida. Metal roofs are not noisy in the rain thanks to the thicker metal roofing material used in South Florida along with the plywood decking and underlayment which also deadens the sound.

CONTACT US NOW: (786) 625-7192

The Leading Professionals In Roof Installation In South Florida. Let Us Prove It To You!